Get high-quality ceramic coating Sarasota to safeguard your car’s paint.

A Comprehensive Overview to the Sorts Of Ceramic Finishing on the Market

Ceramic finishes have actually arised as a pivotal service across different sectors due to their unique buildings and applications. As we discover the distinct features and applications of these finishings, the effects for performance and longevity end up being progressively noticeable, increasing inquiries concerning which kind might finest fit your needs.

Comprehending Ceramic Coatings

Ceramic coverings are sophisticated protective services that have acquired appeal in numerous industries, specifically in automotive and aerospace applications. These finishings contain a liquid polymer that, when healed, forms a long lasting, hydrophobic layer externally of the substrate. This layer offers improved resistance to ecological pollutants, UV radiation, and chemical exposure, therefore prolonging the life and aesthetic charm of the underlying material.

The basic part of ceramic coverings is silica, which adds to their firmness and sturdiness. The application process normally involves surface area prep work, application of the layer, and healing, which can be attained via heat or UV light. Once cured, ceramic coatings display outstanding bonding residential properties, enabling them to adhere strongly to a selection of surface areas, consisting of metals, plastics, and glass.

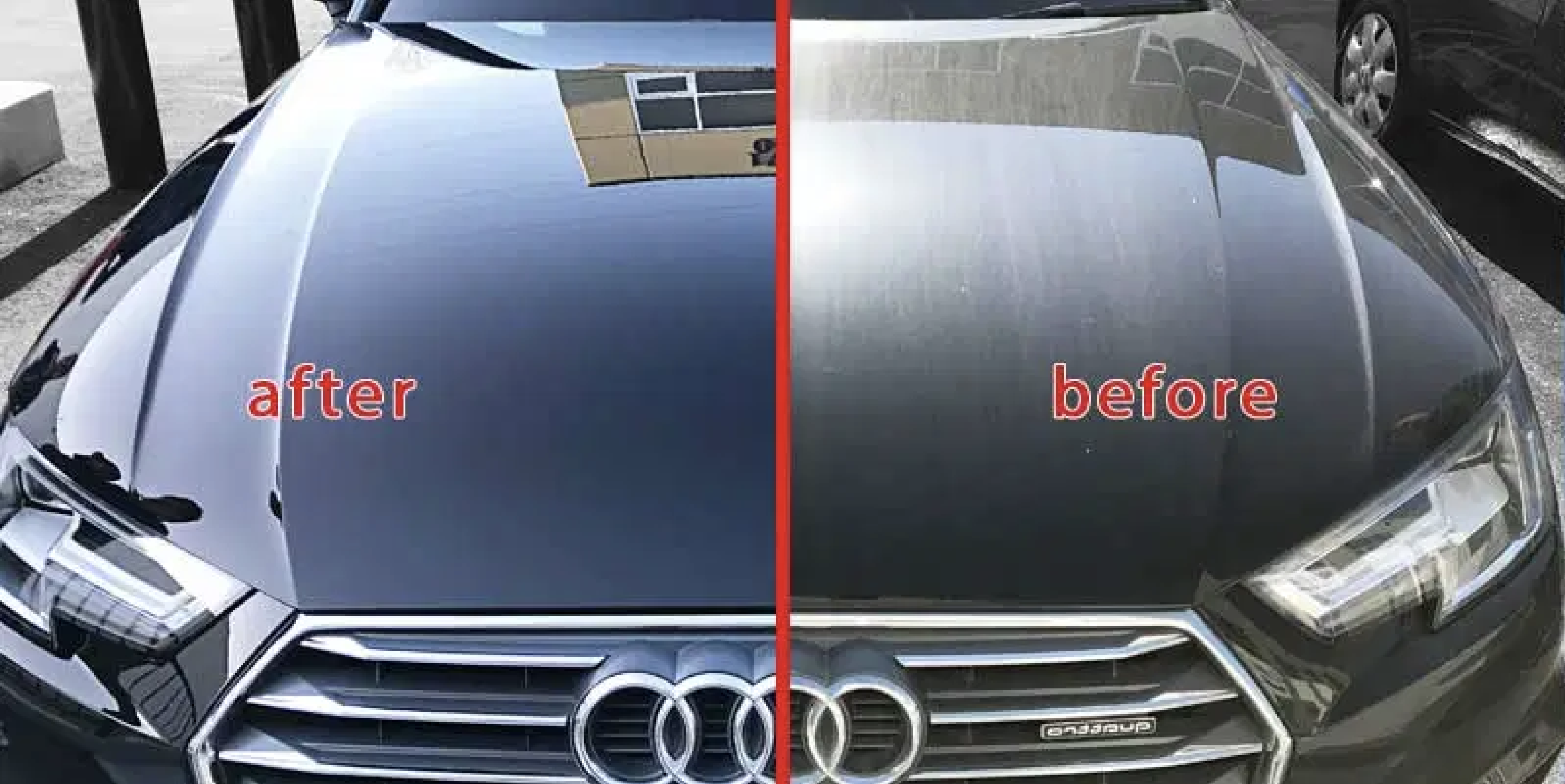

Along with their safety attributes, ceramic finishes additionally supply convenience of maintenance. Their hydrophobic nature decreases the adherence of dust and gunk, making cleansing simpler and less frequent. In general, the adoption of ceramic finishes stands for a considerable advancement in surface defense technology, supplying both useful and aesthetic benefits across numerous markets.

Kinds of Ceramic Coatings

Numerous kinds of ceramic coverings are readily available, each developed to satisfy particular performance needs and applications - Auto Detailing. The most common kinds include:

Silica-based Coatings: These finishings largely include silicon dioxide and are recognized for their longevity and chemical resistance. They are widely made use of in vehicle and industrial applications.

Titanium Dioxide Coatings: Distinguished for their photocatalytic residential or commercial properties, titanium dioxide layers are commonly applied in settings where self-cleaning and antifungal properties are desirable, such as in building materials and auto surfaces.

Zirconia Coatings: Defined by their high-temperature stability and thermal resistance, zirconia layers are used in applications such as wind turbine engines and high-performance vehicle elements.

Alumina Coatings: Exhibiting outstanding firmness and thermal stability, alumina finishes are often made use of in wear-resistant applications, including reducing devices and commercial equipment. - Paint Protection Film

Crossbreed Coatings: Incorporating the residential or commercial properties of numerous products, hybrid layers use boosted efficiency features, making them ideal for special and requiring applications.

Each kind of ceramic finishing offers distinctive objectives, allowing individuals to pick the most suitable option based upon specific ecological problems and efficiency demands.

Advantages of Ceramic Coatings

Coatings play an essential function in enhancing the efficiency and durability of surface areas throughout different markets. Ceramic finishes, particularly, deal many benefits that make them increasingly prominent amongst suppliers and consumers alike. Among the main benefits is their extraordinary sturdiness. These finishings are immune to scrapes, chemicals, and UV you can try here rays, making certain that the underlying surface continues to be safeguarded gradually.

Along with resilience, ceramic coatings supply excellent hydrophobic residential properties, enabling for easy cleansing and maintenance. This water-repellent nature minimizes the adherence of dust, gunk, and other contaminants, which can extend the aesthetic charm and functionality of the surface. Ceramic coatings can considerably enhance thermal resistance, making them suitable for applications that withstand high temperatures.

Application Refine

When applying ceramic finishes, a careful strategy is necessary to accomplish ideal results. A tidy surface area makes sure proper bond of the layer.

Once the surface is prepped, the next action is to apply the ceramic covering. The layer should be used in slim layers, as thicker applications can lead to uneven surfaces.

After application, the finish needs a particular curing time, generally varying from a couple of hours to a full day, depending on the product. Following these steps vigilantly will make best use of the performance and longevity of the ceramic coating, supplying a sturdy safety layer for the surface area.

Maintenance and Durability

To make sure the long life and efficiency of a ceramic finish, routine upkeep is essential. Ceramic finishes, recognized for their sturdiness and safety qualities, need you could look here certain treatment regimens to maximize their life expectancy and efficiency.

In enhancement to regular washing, periodic examinations are essential. Try to find indicators of wear or damage, such as hydrophobic properties reducing or surface area imperfections. If required, a light gloss might be put on revitalize the finish without you could check here removing it away.

Furthermore, the application of a booster spray can improve the coating's hydrophobic impacts and recover its gloss. This is particularly valuable for finishes that have actually remained in use for a prolonged duration. Inevitably, by sticking to these upkeep techniques, one can considerably expand the life of a ceramic layer, making certain that it continues to supply optimum protection versus ecological elements and maintain the aesthetic charm of the car.

Conclusion